Stable Quality

Stable Quality Reasonable Price

Reasonable Price Quick Delivery

Quick DeliveryScissor lift table have widespread applications in industrial and commercial fields, especially in factory workshops, warehouses, logistics centers and other environments where heavy goods need to be efficiently moved. Its unique design and efficient operation make it an ideal choice for these places.

| Model | MK-SL1 | MK-SL2 | MK-SL3 | MK-SL4 | MK-SL5 | MK-SL6 |

| Load Capacity | 500KG | 1000KG | ||||

| Min.Heigh | 28CM | 37CM | 37CM | 43CM | 42CM | 50CM |

| Max.Height | 0.9M | 1.3M | 1.5M | 2M | 1M | 1.7M |

| Table Dimension(cm) | 50*80 | 50*92 | 50*92 | 50*92 | 50*100 | 60*120 |

| Dia.of the wheel | 125MM | 150MM | ||||

| Net Weight | 80KG | 113KG | 117KG | 155KG | 120KG | 230KG |

| Packing Dimensions | 90*51*39CM | 100*51*39CM | 115*55*45 | 130*63*42 | ||

We work directly for our clients and put client’s interests first. Innovation Guides Us As Always

Contact US+

From The Moment Wereceive Your Inquiry, Westart Serving You

All Products Wwill Be Professionally Tested Before Packaging, And Can Only Bepackaged And Stored After100% Passing The Test

20-Foot Container Conventional Products Can Beshipped Within 15 Days,40-Ffoot Container Can Beshipped Within 20 Days

Manufacture And Supply Afull Range Of Lifing And Han.Dling Equipment

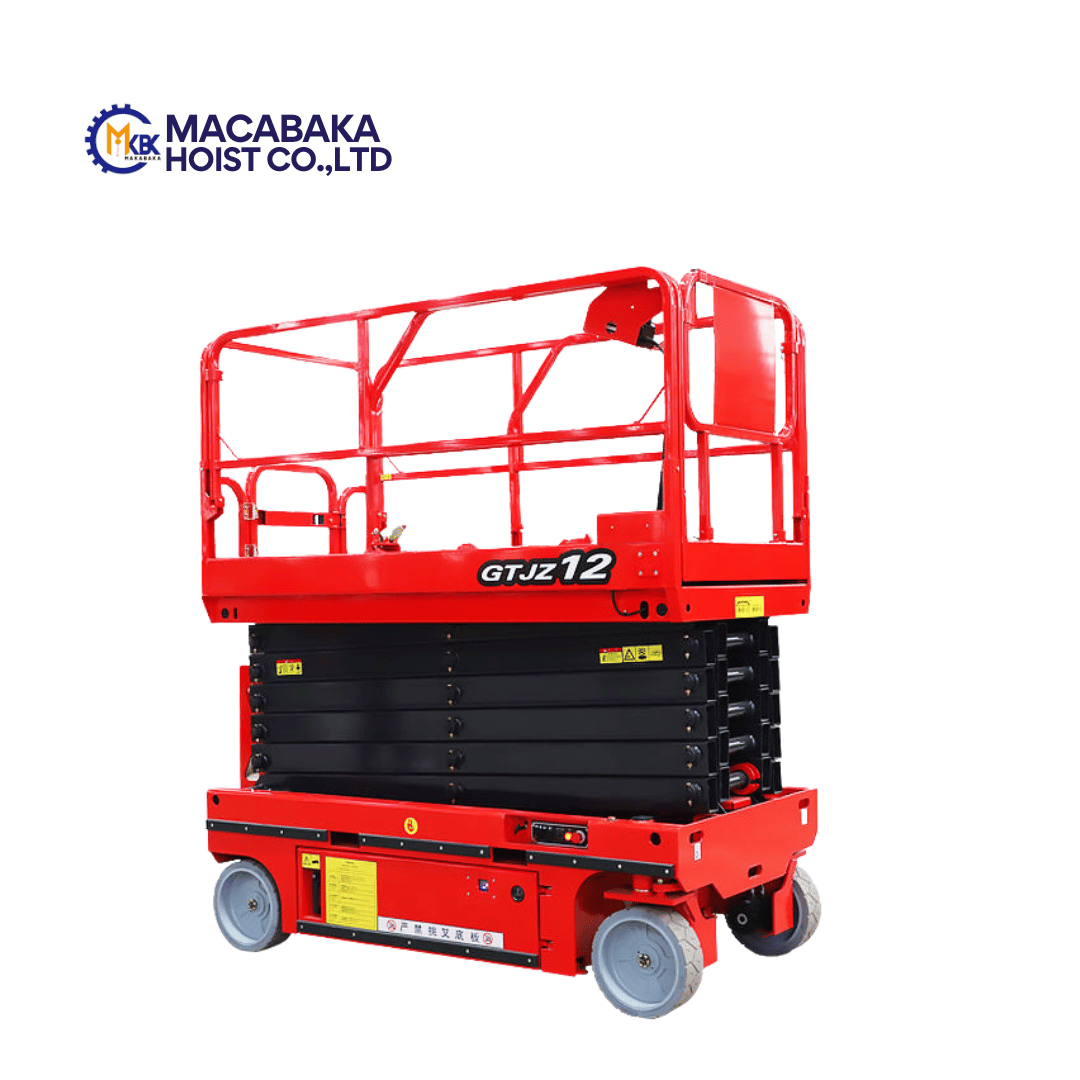

Self Propelled Scissor Lift

Self Propelled Scissor Lift

1.Fully Self-Propelled Operation

2.High Working Efficiency

3.Compact Design for Narrow Spaces

4.Stable and Smooth Lifting

5.Enhanced Safety and Control

Mobile Lifting Platform

Mobile Lifting Platform

1.Flexible Mobility

2.Efficient Lifting Performance

3.Wide Application Range

4.Improved Productivity

5.Enhanced Safety Design

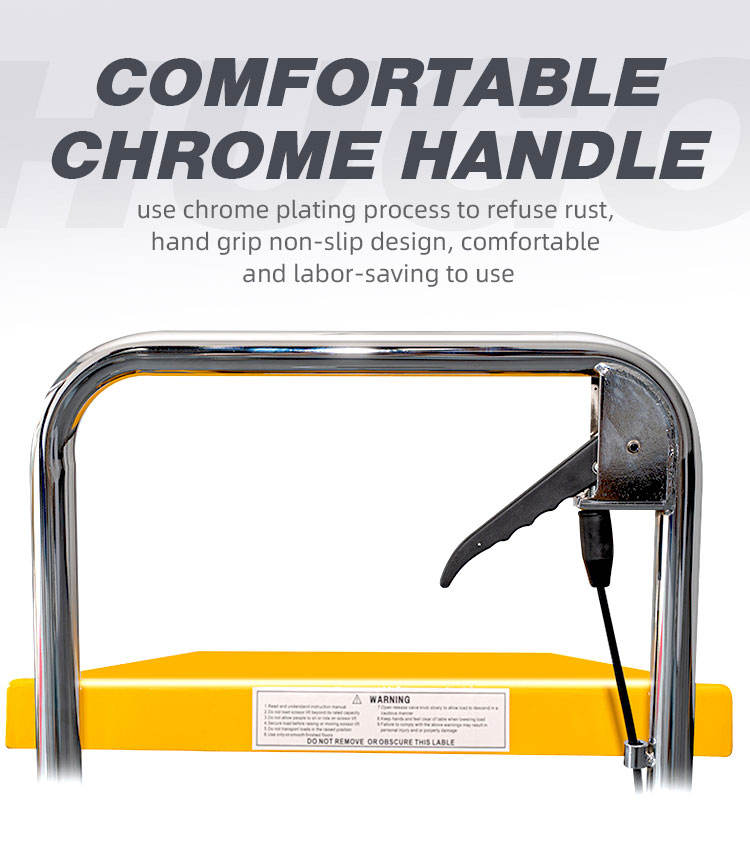

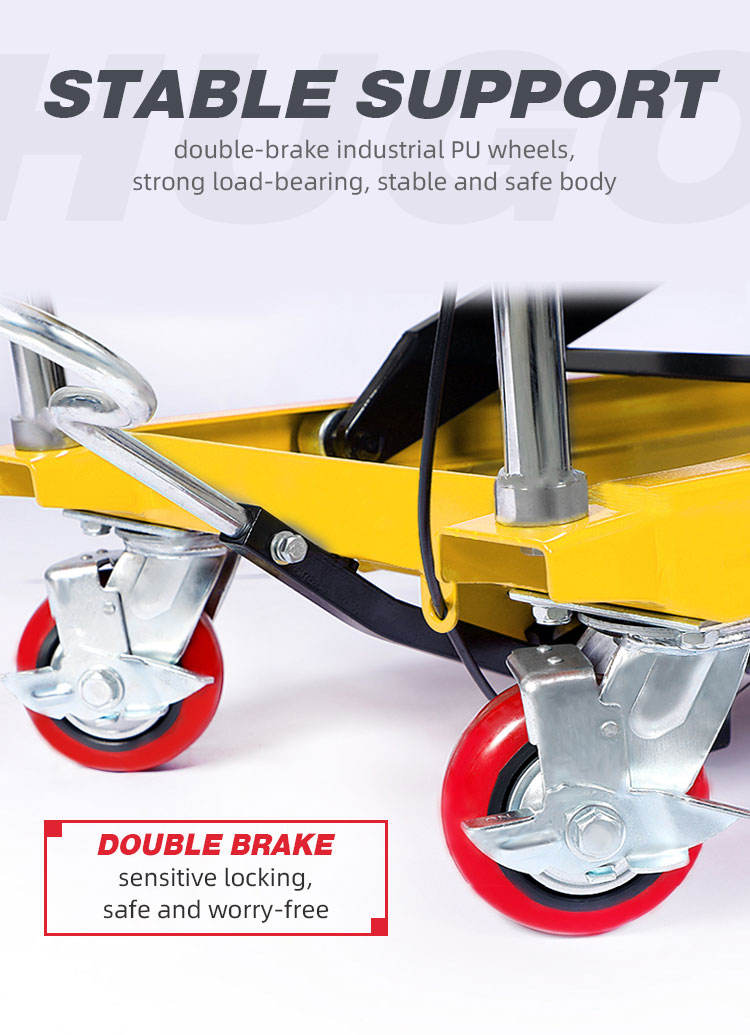

Hydraulic Scissor Lift Table

Hydraulic Scissor Lift Table

1. Easy maneuverability in narrow spaces and tight aisles.

2. Versatile handling for a wide range of weights and sizes.

3.Cost-effective solution with low initial and maintenance costs.

4. lmproved productivity with quicker and more efficient transportation.

5.Enhanced safety features for operator well-being and accident prevention.

Electric Scissor Lift Table

Electric Scissor Lift Table

1.Smooth and Easy Operation

2.Versatile Lifting for Various Loads

3.Cost-Effective and Energy Efficient

4.Improved Productivity and Efficiency

5.Enhanced Safety and Stability