Stable Quality

Stable Quality Reasonable Price

Reasonable Price Quick Delivery

Quick DeliverySteel drum material: Durable and corrosion-resistant, ideal for long-term use.

| Modle | MK-DT1 |

| Rated capacity | 300kg |

| Self weight | 45KG |

| floor clearance | 150-350mm |

| wheel size | 200*50mm |

| Wheel | 3 |

We work directly for our clients and put client’s interests first. Innovation Guides Us As Always

Contact US+

From The Moment Wereceive Your Inquiry, Westart Serving You

All Products Wwill Be Professionally Tested Before Packaging, And Can Only Bepackaged And Stored After100% Passing The Test

20-Foot Container Conventional Products Can Beshipped Within 15 Days,40-Ffoot Container Can Beshipped Within 20 Days

Manufacture And Supply Afull Range Of Lifing And Han.Dling Equipment

Drum Stacker

Drum Stacker

1.The eagle-beak clampsecures drums firmlyto prevent slipping,and is simple to operate.

2. Strong Operational Stability,Enabling Smooth and Even Tilting(Forward/Backward)or Uninterrupted DischargingWithout Jamming or Vibration

3. Equipped with Pressure Relief Valve,Foot-Pedal Lifting,Sealed Anti-Leakage Design,Easy Handling

4..Stable structure, safe and easy to operate

Forklift Drum Clamp

Forklift Drum Clamp

1.strong and reliable gripping mechanism that automatically locks onto the drum during lifting, ensuring the drum remains firmly secured throughout transportation.

2. high-strength steel and a durable powder-coated finish

3. simple structure and easy installation, can be quickly mounted onto most standard forklifts without complex modifications.

4. It is available in different models for handling single or multiple drums and can be customized to match various drum types, load capacities, and working conditions.

5. This attachment is an ideal solution for improving handling efficiency, enhancing safety standards, and optimizing drum logistics operations.

Drum Handling Trolley

Drum Handling Trolley

1.The sealing hydraulic oil cylinder used in the oil drum truck has thecharacteristics of strong sealing performance, large bearing capacityand preventing oil leakage.

2.The nylon ground wheel used in the oil drum truck is durable andwear-resistant, suitable for all kinds of ground, and the resistance issmall when walking, and will not damage the ground.

3. The hydraulic spring used in the oil drum truck has the characteristics ofstrong toughness, suitable elasticity, stable rebound speed, etc., whichmakes the operator more comfortable and convenient when operating the oil drum truck

4.The main body of the oil drum truck is made of thickened steel andwelded by the manipulator, which has a strong carrying capacity and willnot be deformed.

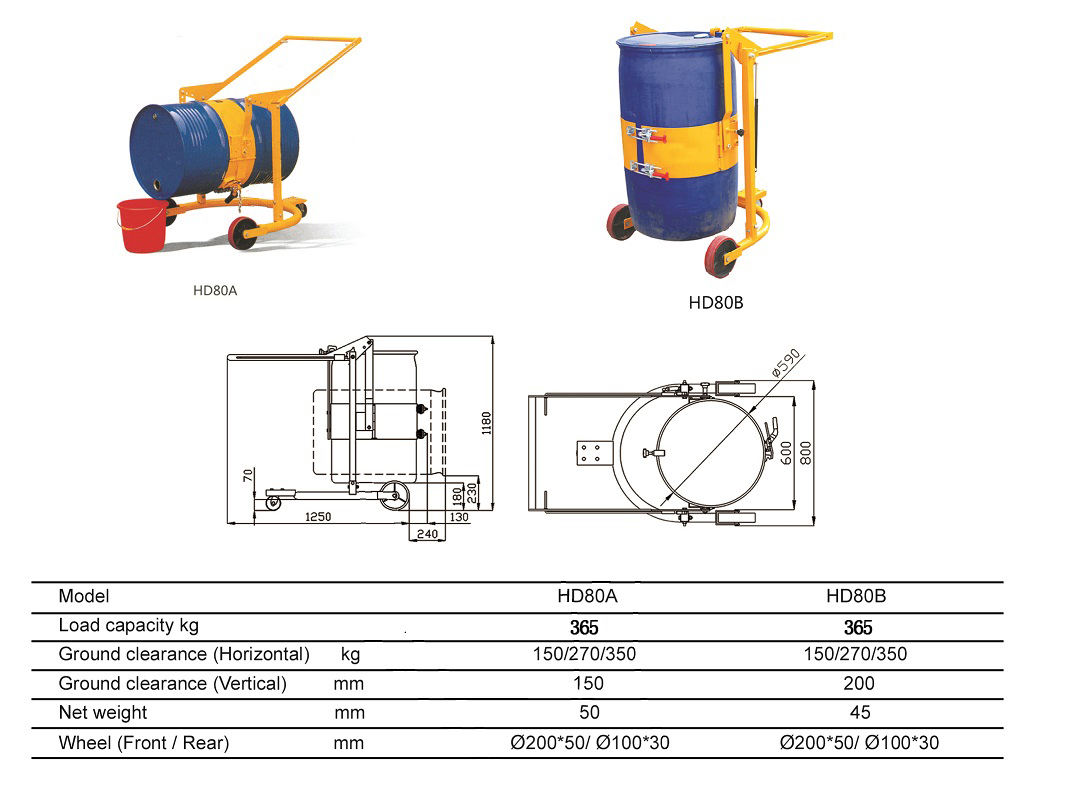

Drum Tilter Trolley

Drum Tilter Trolley

1. Single operator loading, lifting, moving, dispensing, and unloading of 210-liter steel and polyurethane drums.

2. Ratchet drum clamping mechanism and ratchet lifting mechanism.

3. Saddle securing the drum in place during transport.

4. Equipped with 200mm polyurethane roller bearing wheels and 100mm swivel casters.

5. Can lock the drum in a vertical position to prevent spillage, or lock it in a horizontal position to drain.

When unlocked, the drum can be tilted end-to-end to agitate the contents or tilted and manually held at any angle.